JLA – Most Read Articles of 2019! Generating more than 3,600 downloads in 2019, the articles listed below are some of the most read Journal of Laser Applications articles from 2019, all of which have been made free to read, download, and share for a limited time (until Monday, Feb. 3, 2020). Publishing with us […]

Laser Research

Superhydrophobic and Superhydrophilic Functionalization of Engineering Surfaces by Laser Texturing

By Suwas Nikumb, Peter Serles, and Evgueni Bordatchev As seen in ICALEO 2017 and LIA TODAY Nature is a bountiful source of inspiration to advance innovative surface functionalities, processes, and technologies for engineering materials. For example, the super-hydrophobic surface characteristic of the lotus leaf can be recreated by mimicking the microstructure and surface energy […]

Laser direct writing: An effective approach to flexible hybrid electronics

As featured in the LIA TODAY and ICALEO 2017 By Jinguang Cai and Akira Watanabe The development of miniaturized portable and wearable electronic devices has attracted worldwide research attention, due to their increasing integration with human daily life. Different from traditional electronic devices on “hard” boards, such devices should be soft and flexible. A concept […]

Lasers Just Gave us the World’s Fastest Camera

The device has been dubbed T-Cup and is capable of capturing images at over 10 trillion frames a second! “T-Cup” Was developed Jinyang Liang along with Caltech’s Lihong Wang and their colleagues. If the device you are reading this on happens to be a smart phone, you could capture about 30 frames per second. “T-Cup” […]

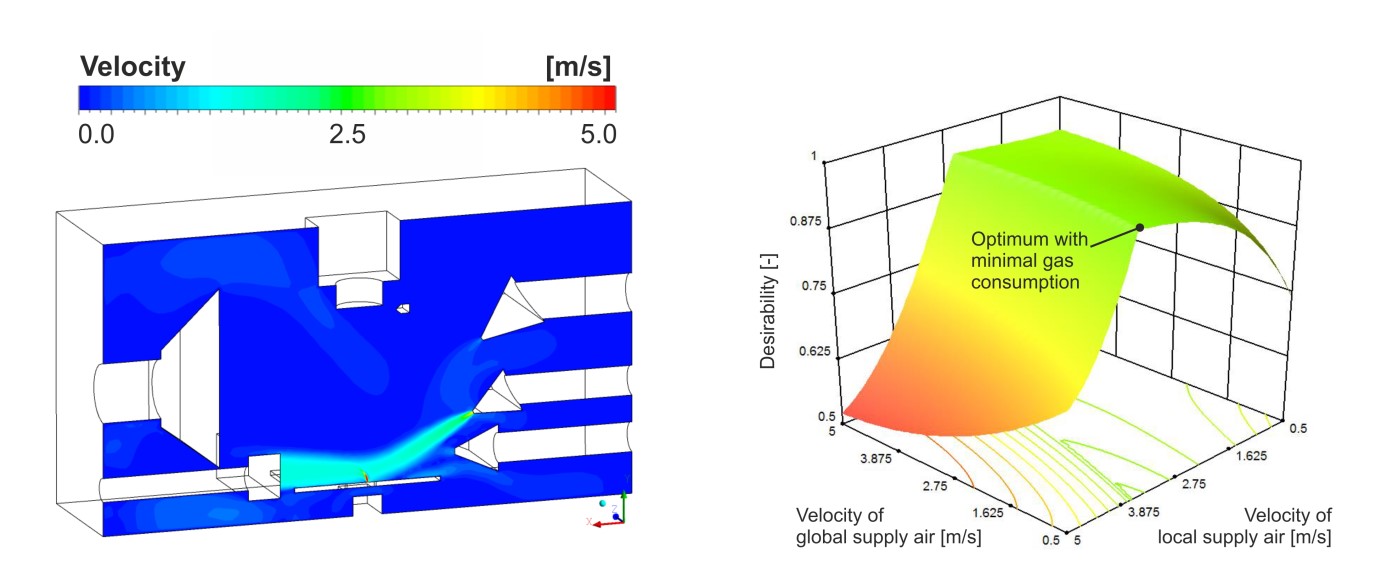

Air Flow Control for Remote Laser Beam Welding

Developers and users of industrial remote laser beam welding applications are often faced with different challenges under the conditions of series production. First, those applications are preferably conducted without any localized gas shielding, and therefore, specific interactions between the laser radiation and the welding fumes are very likely to occur, causing an impairment of the process stability, the reliability and the weld seam quality. Second, welding fume residuals are capable of contaminating workpieces, optical components and other parts of the processing chamber, and they are also able to cause a serious pollution of the cabin atmosphere, because a significant part of the welding fume species is harmful or even toxic and carcinogenic. Each of these points gives a good reason to develop appropriate cabin air flow concepts, but in practice, it is still a challenge to design and optimize the air or gas flow because (i) the conditions of an ideal gas flow regime are uncertain, (ii) different gas flows are able to interact in complex manners, and (iii) it is costly to describe and monitor the gas flow characteristics inside the processing chamber experimentally.