Liège, 7/10/2019 – LASEA, one of the world leaders in laser micromachining, has announced it is tripling its equity and entering a new growth phase in its various markets. The current shareholders (Epimède, SRIW, Noshaq and private shareholders) are backing this operation to the tune of 6.1 million euros (first phase) to which will be […]

Uncategorized

LIA to Present Jamie J. King with R. James Rockwell, Jr. Award at ILSC 2019

ORLANDO, Fla., March 11, 2019 /PRNewswire-PRWeb/ — The Laser Institute (LIA) will recognize Jamie J. King, Certified Laser Safety Officer (CLSO) for Lawrence Livermore National Laboratory, with the R. James Rockwell, Jr. Educational Achievement Award at the International Laser Safety Conference (ILSC). Awarded biennially since 2005, the R. James Rockwell, Jr. Educational Achievement Award honors individuals with outstanding contributions to laser safety […]

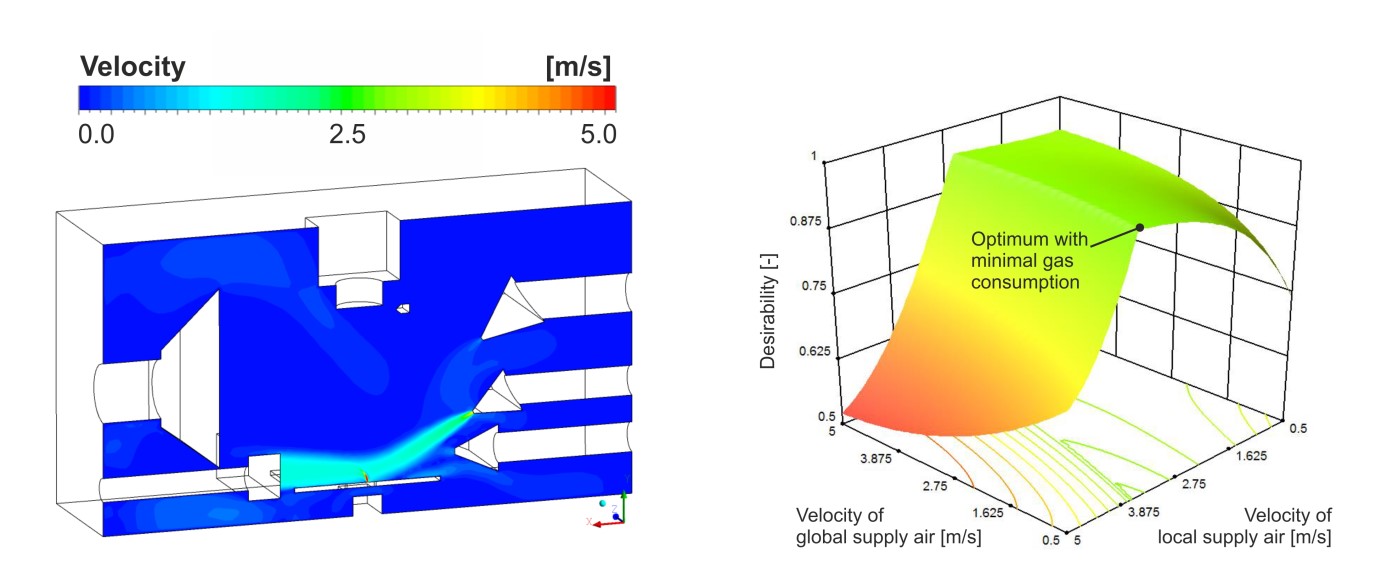

Air Flow Control for Remote Laser Beam Welding

Developers and users of industrial remote laser beam welding applications are often faced with different challenges under the conditions of series production. First, those applications are preferably conducted without any localized gas shielding, and therefore, specific interactions between the laser radiation and the welding fumes are very likely to occur, causing an impairment of the process stability, the reliability and the weld seam quality. Second, welding fume residuals are capable of contaminating workpieces, optical components and other parts of the processing chamber, and they are also able to cause a serious pollution of the cabin atmosphere, because a significant part of the welding fume species is harmful or even toxic and carcinogenic. Each of these points gives a good reason to develop appropriate cabin air flow concepts, but in practice, it is still a challenge to design and optimize the air or gas flow because (i) the conditions of an ideal gas flow regime are uncertain, (ii) different gas flows are able to interact in complex manners, and (iii) it is costly to describe and monitor the gas flow characteristics inside the processing chamber experimentally.

Evaluation Of 3D-Printed Parts By Means Of High-Performance Computer Tomography

Qualification and certification of parts made by AM processes has been identified by various authors [1, 2, 3, 4, 5] as one of the main challenges for the widespread adoption of AM in fabrication of structurally critical components. Traditionally, the qualification of parts is made by extensive non-destructive and destructive tests in a representative sample amount of the final product. This is a slow and expensive process in any kind of production, but in AM processes, it also contradicts many of the identified advantages, i. e. potential to save material and therefore process costs. To solve this problem, the qualification of AM parts demands a different approach, with focus in the research of certification of AM parts based on design and correlations of parameters during manufacturing and non-destructive tests [1, 4, 5].

Highlights from LIA’s Lasers for Manufacturing Event (LME): Prima Power Holds Open House

By Ron Schaeffer Prima Power was an exhibitor at Laser Institute of America’s LME 2018, held March 28-29 at the Renaissance Schaumburg Convention Center, Schaumburg, IL. After show hours on March 28, Prima Power hosted an Open House at its showroom in nearby Arlington Heights, IL. A large group of visitors, composed of laser industry […]