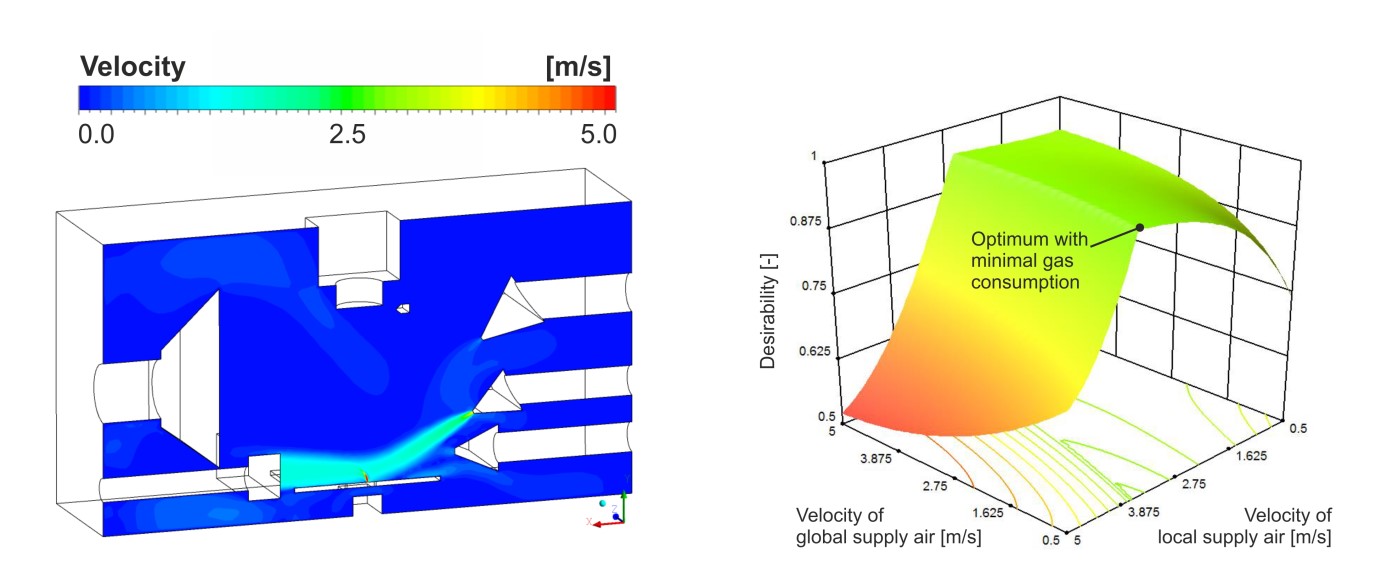

Developers and users of industrial remote laser beam welding applications are often faced with different challenges under the conditions of series production. First, those applications are preferably conducted without any localized gas shielding, and therefore, specific interactions between the laser radiation and the welding fumes are very likely to occur, causing an impairment of the process stability, the reliability and the weld seam quality. Second, welding fume residuals are capable of contaminating workpieces, optical components and other parts of the processing chamber, and they are also able to cause a serious pollution of the cabin atmosphere, because a significant part of the welding fume species is harmful or even toxic and carcinogenic. Each of these points gives a good reason to develop appropriate cabin air flow concepts, but in practice, it is still a challenge to design and optimize the air or gas flow because (i) the conditions of an ideal gas flow regime are uncertain, (ii) different gas flows are able to interact in complex manners, and (iii) it is costly to describe and monitor the gas flow characteristics inside the processing chamber experimentally.

Laser Welding

LIA Introduces Three Laser Safety and Welding Publications to its Online Store

For Immediate Release ORLANDO, FL (August 9, 2016) – Laser Institute of America (LIA) is proud to announce the release of three laser publications now available for purchase in its online store (https://www.lia.org/store), the laser industry’s one-stop-shop for the most valuable and current laser safety and practical applications resources. The publications, which include Laser Safety Tools […]

The Laser Seam Stepper (LSS): A New Fiber Laser Welding Tool

By Michael Wiener In today’s automotive industry — and its high-volume production environment — laser welding has become a well-established joining technology. High productivity, low heat input, and fast welding speed are some of the main advantages of laser welding compared to conventional joining technologies — such as gas metal arc welding (GMAW) or resistance […]

Laser Micro Welding of Aluminum with the Superposition of a Pulsed Diode Laser and a Pulsed Nd:Yag Laser

By Philipp von Witzendorff, Lorenz Gehrmann, Martin Bielenin, Jean-Pierre Bergmann, Stefan Kaierle and Ludger Overmeyer Pulsed laser welding is applied for welding of thin aluminum sheets when the heat affected zone has to be minimized. The pulsed laser process enables a low and precise heat input because the heat dissipates away in between the laser pulses. […]

Welding Characteristics of Foturan Glass Using Ultrashort Laser Pulses

By Isamu Miyamoto, Yasuhiro Okamoto, Kristian Cvecek, Michael Schmidt, Henry Helvajian While glass is widely used in different industrial field due to its excellent physical and chemical properties, there exist no reliable joining procedures of glass at the moment. We have developed a novel fusion welding procedure of glass that can weld glass even with […]