As featured in the LIA TODAY and ICALEO 2017 By Jinguang Cai and Akira Watanabe The development of miniaturized portable and wearable electronic devices has attracted worldwide research attention, due to their increasing integration with human daily life. Different from traditional electronic devices on “hard” boards, such devices should be soft and flexible. A concept […]

Laser Editorials

Inventors Synthesize Graphene with Lasers

As featured in the LIA TODAY By Liliana Caldero Graphene – it’s the two-dimensional (2D) allotrope of carbon atoms that ignited the imaginations of researchers across the globe. Heralded as a ‘miracle material’, its potential seemed limitless and it was predicted to usher in the next generation of technology. Flexible, stronger than steel, transparent, lightweight, […]

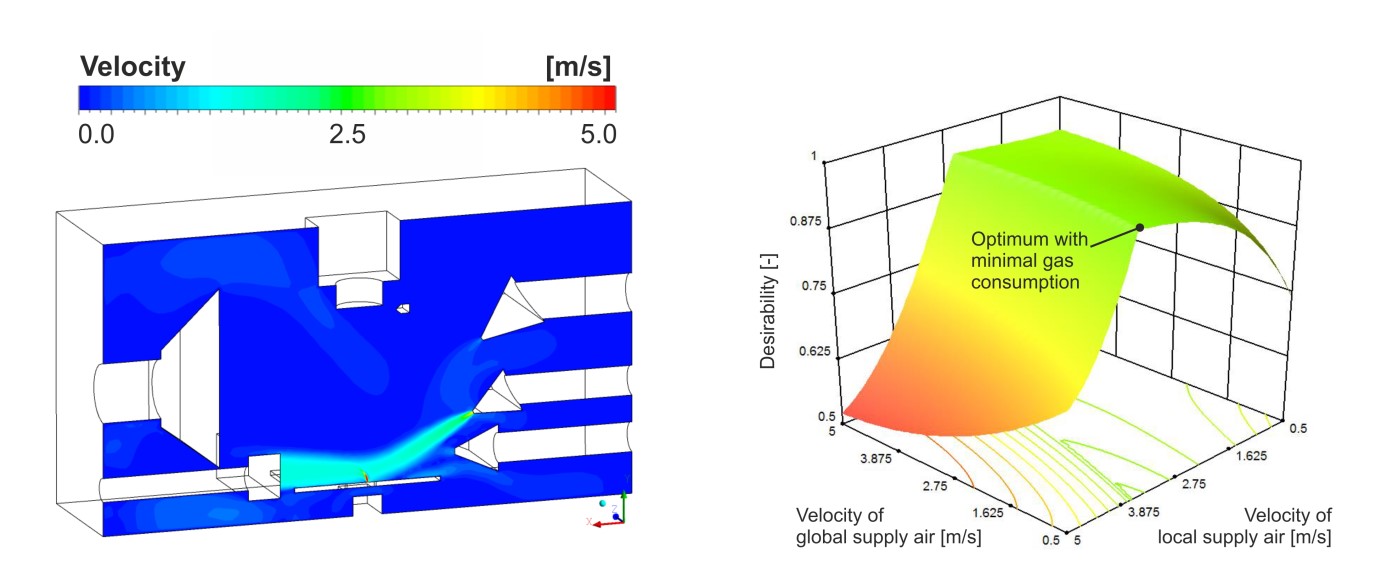

Air Flow Control for Remote Laser Beam Welding

Developers and users of industrial remote laser beam welding applications are often faced with different challenges under the conditions of series production. First, those applications are preferably conducted without any localized gas shielding, and therefore, specific interactions between the laser radiation and the welding fumes are very likely to occur, causing an impairment of the process stability, the reliability and the weld seam quality. Second, welding fume residuals are capable of contaminating workpieces, optical components and other parts of the processing chamber, and they are also able to cause a serious pollution of the cabin atmosphere, because a significant part of the welding fume species is harmful or even toxic and carcinogenic. Each of these points gives a good reason to develop appropriate cabin air flow concepts, but in practice, it is still a challenge to design and optimize the air or gas flow because (i) the conditions of an ideal gas flow regime are uncertain, (ii) different gas flows are able to interact in complex manners, and (iii) it is costly to describe and monitor the gas flow characteristics inside the processing chamber experimentally.

Combination of Short and Ultrashort Pulse Laser Processing for Productive Large Scale Structuring of 3D Plastic Mould Steel

By: Andreas Brenner, Fraunhofer-Institute for Laser Technology and Fabian Kurzidim, Volkswagen AG Increasing demand for surface functionality Surface functionality is an increasing and crucial factor for the success and acceptance of a product. Through structured surfaces products can gain additional functions. In the automotive industry for example microstructures enable friction reduction in combustion engines or optimize […]

2017 Laser Market Review

By: David Belforte, Industrial Laser Solutions In last year’s 2016 report, I opened with comments about the troubling times, political, cultural and economic, we lived in and then expounded on the industrial laser industry seeming to defy bad news with its own good economic news. Well, I could have copied that report, changed a few […]