By Jamie J. King, CLSO

The design of a laser laboratory is not only critical to its overall functionality, but more importantly to the safety of those who work in and around it. The safe planning of a laboratory is no accident. From conception to commissioning of the laser, safety must be involved in every step of the process.

Each situation presents unique challenges with equally differing solutions. It is up to, and the responsibility of, the Laser Safety Officer (LSO) to ensure that each Laser Controlled Area (LCA) is fashioned in the safest way possible. American National Standards Institute (ANSI) Z136.1-2014 states that the total laser hazard evaluation is influenced by:

- The laser’s capability of injuring personnel or interfering with task performance.

- The environment in which the laser is used.

- The personnel who may be exposed to the laser.

The laser part sounds like the simplest problem to solve. This may have been true in the days before ultrashort pulse lasers, OPAs, nonlinear optics, and high-average power lasers, to name a few. Today you may be faced with several of these aspects all at once. The LSO must be part of the design phase very early on to ensure all issues are addressed.

The environment in which the laser will be used is probably the biggest variable to deal with. Being involved in the process early will ensure the crafting of a space that depicts excellence in terms of form, function, and safety. Coming in late can be a disaster, requiring patchwork fixes that look sloppy and may not be safe.

You can minimize the extent of personnel potentially exposed by controlling the design of the laser space. Reducing the potential for exposure to personnel decreases the hazard and downgrades the level of safety training required. This will lessen the overall per annum operational expenses.

In setting up a laser lab, the pitfalls can be a plenty. Without forethought, you won’t recognize them until the space is completely built out and you are ready to operate. Any new design or remodel should incorporate the use of a computer-aided design (CAD). With this, you can start to envision the potential problems that might unfold otherwise. Working with the end user, you can discuss the intended operation and process flow. Some of the potential issues you will uncover are:

- Entryway controls – whether defeatable or non-defeatable Safety Interlock System (SIS) you can determine if you might have potential laser beam outside of the LCA.

- Ergonomics – what tasks/operations will be performed frequently? Design the height of the optical table accordingly. Can the worker perform all actions comfortably?

- Utilities – electrical cables, water lines, fire suppression, and ventilation are best thought out and designed early on. Having these engineered in at the beginning prevents patch work fixes after, which surely will create slip/trip/fall issues.

In looking at the layout of the optical tables, you can determine how best to plan the beam path. It is never a good idea to direct a laser beam towards the entryway. If you operate in a seismically active area, you should either brace your tables or locate them such that egress will not be inhibited in the case of an earthquake. As soon as an optical table is installed in the space you should electrically bond it to ground. You never know that will be put on the table in the future. Do not make the mistake of connecting a bonding strap to the bottom of the table unless you ensure there is electrical continuity between the top and bottom plate.

Something to keep in mind in setting up a safe laser operation is that you want to control the hazard as close to the source as possible. Things to look at here are:

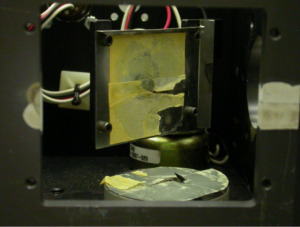

- Beam Blocks/Barriers/Enclosures – beam blocks are placed at the end of beam lines or behind optics and are expected to take the power/energy of a full beam. Choice of materials is crucial here in that you don’t want to select something that is highly reflective or can’t handle the thermal load of the incident beam. Remember that the go-to material of black anodized aluminum is very reflective in the near infrared. Barriers are installed beyond beam blocks, usually around the perimeter of an optical table. They are only meant to see a diffusely scattered beam. Barriers can also be used to block an area, preventing line of site into an LCA. Barrier materials can range from laser curtain material to metal panels or even walls. When installing these types of barriers, one must ensure that physical stature of the worker is considered. This will ensure that the height of the barrier is adequate to protect all outside of the LCA. In more mature and static operations, one can employ an enclosure to take the laser hazard away from the worker. For truly Class 1, the panels must be either interlocked or require a tool for removal.

- Shutters – this is one of the most significant components of a safe operating laser. Limit the open space between source and shutter. Is the shutter in place? This may seem like a ridiculous question, but if your SIS does not have feedback capabilities, how do you know it is even there? Shutters should be “fail-safe,” meaning they will close on a failure. Shutters can and do fail internally and may need to be inspected to ensure proper operation. Failures may be broken blades, mirrors, levers, and even drilled holes.

The use of multiple wavelengths creates a nightmare when trying to find adequate laser protective eyewear. Early involvement of the LSO in conjunction with your laser eyewear vendor can help determine what wavelengths can and cannot be blocked. A safe worker is one who can adequately see what they are doing.

What about high intensity/high power lasers? This presents another set of unique challenges altogether. At levels of >1015 W/cm2, the generation of ionizing radiation is possible. A 25kW laser beam with a peak irradiance of ~10 kW/cm2 can cut through simple drywall in a second. With diffuse reflections being the main concern for barriers and enclosures, this may become a real issue. Limited commercially available items rated at these high outputs may necessitate that you become your own tester of materials. In this realm, you are better off just removing the worker from the hazard and go with remote operations.

The result of a well-planned laser laboratory not only promotes pride in the team that will use it, but it fosters safety.

How? The space will be well engineered from the start with safety built-in. There is less reliance on administrative controls, and with the LSO input from the start; the worker sees that their safety is the utmost concern.