Interview by Liliana Caldero

As featured in LIA TODAY July/August 2019.

Laser researchers from Bundesanstalt für Materialforschung und -prüfung (BAM) have teamed up with medical researchers from Johannes Kepler Universität Linz (JKU) and Kepler Universitätsklinikum Linz (KUK) in a European research project to show the potential of laser materials processing for suppressing the adhesion of human cells to titanium alloy implants such as miniature pacemakers. This is only one of many research projects investigating the potential uses of surface functionalization. With the use of lasers, technical surfaces can be structured at nano- and micro-scales to mimic textures found in nature, copying the unique characteristics that make them hydrophobic, anti-bacterial, or anti-reflective; this is known as surface functionalization. In most cases, this type of processing reduces or even removes the need for certain chemical coatings.

The field of laser-based surface functionalization is expanding rapidly and new potential applications abound; this technology offers innovative solutions for biotechnology, automotive manufacturing, and machine building. As with most new solutions, the big question is how to make it fast and scalable to promote industry-wide adoption

According to Camilo Florian-Baron of BAM, the trick is using linearly polarized high-intensity ultrashort laser pulses to create laser-induced periodic surface structures, or LIPSS, which can produce these desirable biomimetic properties. With advancements in fast laser scanning heads and recent high-repetition rate ultra-short pulsed femtosecond lasers, surface functionalization with LIPSS is becoming more available for R&D and manufacturing. Florian-Baron and his research team are investigating the future of LIPSS applications. With more than 50 publications on LIPSS coming from BAM in the past decade, the group is among the leading institutions progressing the understanding of the interaction between ultrashort laser pulses and matter for micro- and nano-fabrication of materials[1]. Florian-Baron will be presenting at ICALEO 2019 on the latest applications of surface functionalization through LIPSS. He shared with LIA about some of the unexplored potential of this emerging field and some of the interesting projects his team has been honored to work on.

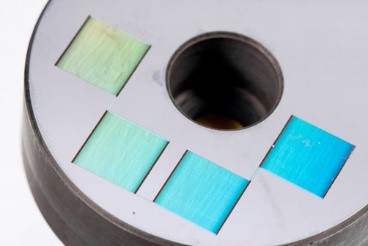

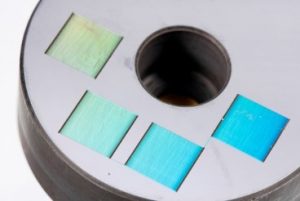

CFB: Usually, materials processing at industrial scales with lasers requires the scanning of the sample of interest with tightly focused laser beams or sweeping the beam on a static sample surface. It means that the micro- and nanofabrication over large areas could take a long time due to the need of irradiating line-by-line or spot-by-spot until the desired machining process is completed. In contrast, laser-induced periodic surface structures (LIPSS) can be fabricated on virtually any material when irradiated with linearly polarized high-intensity ultrashort laser pulses, typically under loosely focusing conditions (large beam spots). The morphology of LIPSS corresponds to parallel arranged period lines featuring periods that can be controlled between only ~100 nm and a few micrometers. Their orientation is strongly influenced by the laser beam polarization used. It means that it is possible, for example, to produce nanometric spaced lines all perpendicular to the laser polarization with a laser beam size at the irradiated surface that is 1000 times bigger than their periodicity covering a larger area with nanostructures faster than conventional laser-direct writing. In an additive approach, these surface nanostructures can be easily superimposed to other surface microstructures, resulting in hybrid surface structures with multiscale surface roughnesses. Through all these surface topographies, along with accompanying laser-induced chemical alterations at the surface, different surface functionalizations can be realized, ranging from structural colorization or antireflective properties (as on certain butterflies), over a control of surface hydrophilicity/-phobicity (as on lotus leaves), and toward unidirectional liquid transport (as realized by moisture-harvesting lizards or bark bugs).

Techniques based on lasers could be defined as contactless digital manufacturing techniques, currently constituting a real industrial- revolution that is transforming the production processes from the early stages of research and development to mass production and marketing [2]. The biggest difference in comparison with other fabrication methods is the possibility to perform design changes using only mouse clicks instead of modifying an already fabricated prototype, resulting in a faster, cheaper and more efficient way of materials processing. Besides that, the current advancements in fast laser scanning heads, combined with high-repetition rate femtosecond lasers allow producing LIPSS at industrially relevant scales and processing speeds, which in the end will be translated into cheaper fabrication costs at higher production rates. Importantly, the whole fabrication process is compatible and reproducible at room temperature and air atmosphere, which is very attractive to most industries that work under similar conditions.

LIA: Your research team has been investigating the mechanisms responsible for the formation of LIPSS to better understand how and when those structures can be formed; what are some of the exciting applications you are researching?

CFB: Our research group is specialized in developing strategies based on lasers to understand the mechanisms of interaction between ultrashort laser pulses and matter, to micro- and nanofabricate materials for specific applications.

Last year, we successfully finished a 3-year international research project funded by the European Commission called LiNaBioFluid [3] where one of the goals was to produce LIPSS on industrially relevant materials and scales to decrease the friction coefficient in tribological applications, as well as developing strategies based on LIPSS for passive fluid transport applications, including commercial lubricants, all based in biomimicking structures found in nature.

As a continuation of this project, currently we are working in another European project called CellFreeImplant [4] (see the link below) that uses LIPSS to avoid unwanted cell growth on medical devices, such as smart medical implants. The promising results are at present in the hands of our medical project partners with close collaborations with a large pacemaker manufacturer to potentially take this laser-based approach for so-called ‘leadless’ pacemakers to real patients in the future.

One of the most exciting feelings when researching LIPSS is that the variety of the current applications are spread over different technological areas. On one hand, this allows us to learn more

about the real producer and manufacturer problems, while at the same time solving them in an efficient way. On the other hand, and personally, with the research that we are currently doing at

BAM, I feel that I am not only achieving milestones in a research project to fulfill it, I think that one day the research, time and resources we are investing could be applied in this particular case to real medical devices that any person can benefit from. In the end, the feeling is that with our tiny steps, we are making the world a better place.

LIA: With all that is being done already, what additional research would you like to see happen in this field?

CFB: Currently, the understanding of the formation dynamics achieved by the growing community of scientists researching LIPSS have allowed the development of different applications in different and diverse fields. However, due to the many different and specific conditions needed to fabricate them, a general model that includes all the possible experimental outcomes in the different materials is not available yet. More efforts should be focused on developing more complete models that will provide a deeper understanding of the formation mechanisms and

laser-matter interaction dynamics that give rise to LIPSS structures. Consequently, with more understanding of the mechanisms involved, novel and innovative applications could emerge.

There are several areas where LIPSS could be useful but currently are barely explored, such as the case of catalytic and self-cleaning surfaces, antireflective treatments based on nanostructures instead of organic or inorganic coatings and perhaps bacterial or antibacterial surfaces for food manufacturing or applications in medicine [1,4,5].

From a practical point of view, the production speed of LIPSS is currently further boosted up by several research groups in Germany, France and Spain, featuring novel scanner technologies based on polygon scanners, along with high repetition rate ultrashort laser sources reaching MHz to GHz pulse repetition rates.

References

- http://doi.org/10.1109/JSTQE.2016.2614183 : Laser-induced Periodic Surface Structures – A Scientific Evergreen (Open access)

- https://www.tdx.cat/bitstream/10803/400403/1/CFB_THESIS.pdf

- https://www.bam.de/Content/EN/Standard-Articles/Topics/Energy/article-linabiofluid.html

- https://www.researchgate.net/project/CellFreeImplant-Cell-free-Ti-based-Medical-Implants-due-to-Laser-induced-Microstructures-H2020-FETOPEN-4-2016-2017-CSA.

- https://doi.org/10.1007/s00339-017-1352-0 (Open access)

- https://doi.org/10.1016/j.apsusc.2017.02.174

See Camilo present, “Surface Functionalization by Laser-Induced Periodic Surface Structures“ (Authors: Camilo Florian-Baron, Sabrina V. Kirner, örg Krüger, Jörn Bonse) at the Laser Nanomanufacturing Conference Track on October 8, 2019. Register for ICALEO here: www.lia.org/conferences/icaleo

SOURCE: https://issuu.com/marketlia/docs/lia_today_augsept-2019/10?fr=sZjFhZTIzMzQwNg