By Craig Bratt & Rahul Patwa

The brilliant light of the laser promises unlimited possibilities for materials processing. Its use in manufacturing dates back to the late 1960s where laser drilling was developed for jet engine components. As laser technology has progressed, fast-paced advances in computers and sensor technologies have enabled the development of improved process monitoring devices which has further enhanced the performance, reliability and ease of use of industrial laser systems.

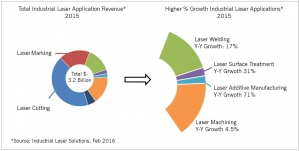

In 2014, the total global market for laser systems for material processing which include both the source and the components was $9.2 Billion (Source: Optech Consulting, VDMA). From this, the total global laser source revenue was $2.9 Billion, according to the data presented by Industrial Laser Solutions (Feb 2016). In 2015, this revenue (only the global laser source revenue) increased by 6.9% to $3.2 Billion. Although, the largest market share has been and continues to be (61% in 2015) in the laser cutting and laser marking/engraving, their % year-over-year growth has been limited to <5%. More interestingly, the higher % Y-O-Y growth areas are laser welding (17%), laser surface treatment (31%) and laser additive manufacturing (71%).

In this article, we present a clear view of how advances in laser power and beam quality along with a significant drop in laser cost per watt and improved laser wall plug efficiency has contributed to major innovations in laser material processing. We have identified four broad laser processing segments and analyzed what is driving innovation.

Manufacturers in many industries have long used laser welding to tackle traditional welding challenges, but laser welding technologies are evolving for even greater utility. Hybrid welding where laser welding is combined with other conventional arc welding methods such as GMAW (MIG) and GTAW (TIG), laser welding with filler wire, and part pre-heating have been successfully implemented in Industry. This has been possible now due to the availability of higher power lasers at lower cost. In turn, materials that were considered difficult to weld until now such as higher carbon steels and cast iron can now be successfully laser welded. The additional filler material changes the composition of the weld, preventing the formation of hard and brittle microstructures. Likewise, induction preheating can be used to help prevent cracking due to martensite formation by slowing down the cooling rate after welding. For instance, in an automotive transmission part, a bolting process was replaced with laser welding, cost savings were achieved through reduced material and processing costs (drilling operations / bolting operations and the bolts themselves), and an overall part weight reduction was accomplished with a more efficient production method using laser technology.

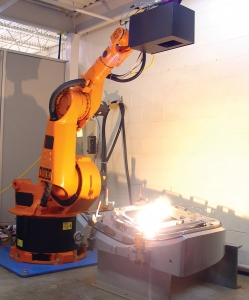

Remote laser welding is another laser welding process which dramatically reduces welding process cycle times compared to conventional welding and is now possible due to availability of higher beam quality lasers and high speed scanners. It involves the use of moving optics in order to rapidly scan the laser beam across the workpiece over large distances both for high speed and for high precision point to point movement.

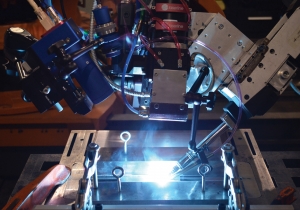

To capture the higher potential of laser welding, there has been substantial yet continuous development in laser welding head technology which includes the welding optics themselves and also the sensor optics. Some of these process monitoring technologies have been in development for some time. Some are not yet ready for application at scale. But camera based laser monitoring is now at a point where its greater reliability and lower cost is starting to make sense for high power welding applications.

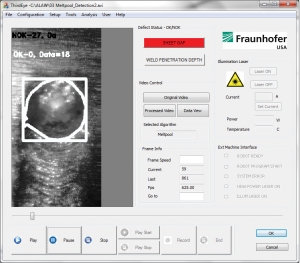

Fraunhofer CLA has developed a high speed camera vision system which can record the welding process in high clarity in real-time and provide both image and video data from the process. This information is processed and calibrated with reference data based on pre-determined actual ‘good’ weld measurements using reinforcement learning. Using customized image processing software algorithms, it is possible to detect many of the most common weld defects.

One laser processing technology which has recently been moving up to forefront of innovative, or even disruptive technologies is laser additive manufacturing (LAM). This process uses laser beam as heat source and is primarily divided in two processes: Selective laser melting (SLM) and Laser metal deposition (LMD).

In the SLM process, a layer of powder is deposited on a build platform and then a rapidly scanned laser beam fuses powder together in the right shape and multiple thin powder layers are deposited to create complex 3D parts.

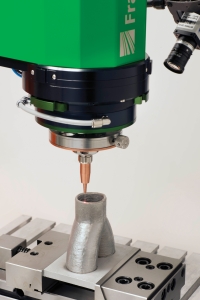

In the LMD process (also known as direct energy deposition or laser cladding), the laser is used to melt metal powder fed through the nozzle which is then deposited in layers onto a substrate, which results in a full metallurgical bond with a small heat affected zone and minimal dilution. It has been developed for surface wear and corrosion coatings, component repairs/remanufacturing, and generation of complete components from scratch.

Two other variations of LMD—hot/cold wire cladding and internal diameter cladding—have now evolved into successful industrial processes and are now widely used in the oil industry, agriculture, power generation and remanufacturing sectors. A recent key development by Fraunhofer IWS is a new coax laser deposition head COAXwireTM which provides

omni-directional welding performance for the use of metallic wires as filler material which is of particular use for 3D build up additive manufacturing of metallic components.

One area of laser material processing that has benefitted the most from technology improvements in both spatial and temporal properties of the laser is laser machining. In addition, the advent of lower cost and smaller footprint laser power sources has lead to much wider industrial adoption of laser technology. The latest generation of pulsed lasers with pulse lengths—from millisecond all the way to femtosecond—has led to a rich pipeline of innovations impacting virtually every manufacturing industry. For example, laser cutting of battery electrodes can produce excellent cut quality and achieve high cutting speeds for application in lithium-ion battery cell production. Similarly lasers can be used for coating removal for electrical contacts on battery foils. Large area coating removal for paint stripping, deoxidization, mold and die cleaning or removal of special coatings is conducted by applying high power lasers. Lasers are also used for high rate drilling process for up to 15,000 holes/second.

In summary, the current pace of innovations leading to new laser technologies and products is constantly increasing with a wide array of new applications being developed for every industry imaginable.

Craig Bratt, Executive Director, Fraunhofer USA, Center for Laser Applications, cbratt@fraunhofer.org

Rahul Patwa, Project Manager, Fraunhofer USA, Center for Laser Applications, rpatwa@fraunhofer.org