In 1997, John O’Connell and Ronald Schaeffer founded PhotoMachining, Inc., a world leader in precision micromachining applications.

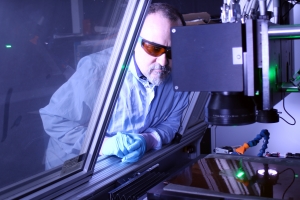

The company specializes in the use of Ultraviolet (UV) and Ultra Short Pulse (USP) lasers. Their lasers come in

a wide variety of wavelengths, which enables them to provide the laser industry with laser micromachining, contract manufacturing, and laser micro machining systems for industrial applications specific to customer requests.

“The development of laser technology has occurred to a great extent over the last 20 years and we have always tried to have the newest lasers available,” said Dr. Ronald Schaeffer, Chief Executive Officer with PhotoMachining. “We were at the forefront of developing novel laser techniques using high pulse rate USP lasers with both fixed optics and galvo scanners.”

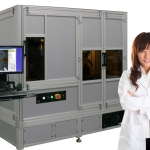

Their team of approximately 25 employees make up two divisions: the Systems Division and the Job Shop Division. Both divisions work together to create innovative systems for their customers’ unique industry needs. The company’s services reach a large variety of markets, which include medical devices, microelectronics, and semiconductors. They have even collaborated on projects related to aerospace and defense.

“We are proud to deliver products to our customers that give them a competitive edge,” said Schaeffer. “We are particularly proud of the processes we have specifically developed for some of the leading medical device manufacturers, which have greatly reduced costs and downtime for our clients.” PhotoMachining, Inc. is continuously trying to innovate and grow. “Our staff is highly motivated to tackle some of the most difficult manufacturing processes regarding precision and economic viability in a production environment,” Schaeffer said. “It requires multiple talents in laser material interaction, systems integration, automation and software to produce highly reliable laser machining systems.”

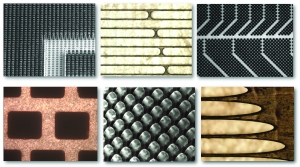

Based out of Pelham, New Hampshire, the company is looking forward to exploring new initiatives. According to Schaeffer, one such initiative is, “3D printing in optically clear materials through Selective Laser Etching (SLE) with LightFab.”

“The SLE process involves exposing hard brittle and otherwise transparent materials like

Quartz and Fused Silica to USP laser light and then chemically etching the exposed area away, where etching selectivity after laser exposure is enhanced over a thousand times,” Schaeffer said. “This method makes 3D precision parts by essentially 3D printing the pattern inside the bulk of the material. SLE is expected to play a major role in many manufacturing processes such as microfluidics.”

PhotoMachining Inc., an LIA corporate member since 2005, actively participates in a number of networking opportunities, allowing them to rub elbows with industry leaders, scientists, and investors from around the world.

“We are active participants at ICALEO and LME conferences and find that LIA is a great place to meet others involved in the laser industry,” Schaeffer said. “LIA is like home.”

The company is always looking towards the future by working alongside new companies with fresh ideas. “Although we work with Fortune 500 corporations,” said O’Connell. “It is gratifying to help startups by producing a handful of prototypes and developing economically viable full production volumes.”

Ron Schaeffer is an active educator within the laser community and has given countless seminars on laser technology and laser materials processing. For an example of his work, here is a short video on “How Lasers Work”. For more information about PhotoMachining Inc., please visit http://www.photomachining.com/

This corporate member feature was written by Brandon Kalloo in collaboration with PhotoMachining, Inc.