By Raymond Walker & Bryant Walker

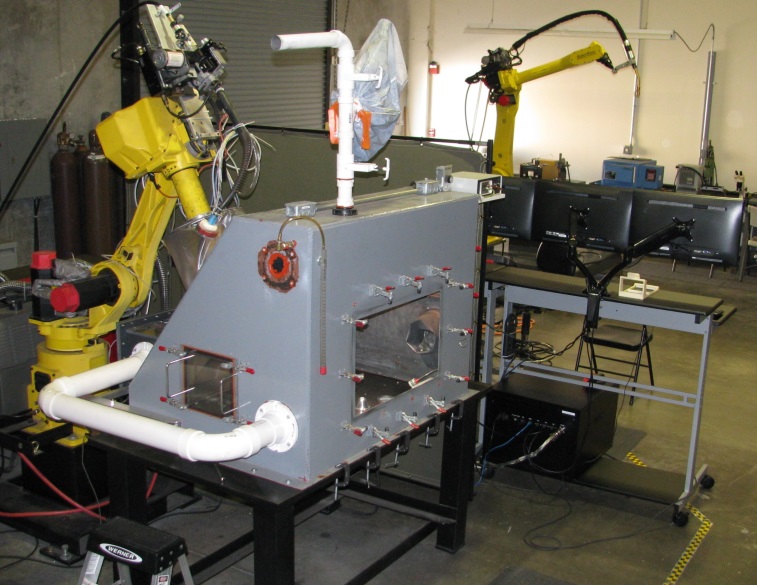

Expanding directed-energy additive manufacturing into very large parts based on a low-cost platform has been a thrust of Keystone Synergistic Enterprises, Inc. for the past decade. Keystone has successfully produced directed-energy additive manufacturing (AM) parts using a robotic pulsed arc platform enhanced by a suite of integrated process controls that provides a level of uniformity needed for a qualified additive manufacturing capability. To expand beyond laser powder, laser wire feed and electron beam (EB) wire feed AM processes, Keystone has established a very low-cost AM capability using the robotic arc-based process capable of making very large parts. Figure 1 shows the Keystone Robotic AM work cell for large-scale parts.

In the late 1990s and early 2000s, additive manufacturing was being seriously considered for a limited number of F35 airframe components, but that small market of parts was far from being a sustaining business case for a supplier base in additive manufacturing. While numerous airframe and gas turbine engine makers were investigating additive manufacturing, only part demonstrations, test parts and the production of test blocks of AM material were produced, representing a very limited volume of AM parts.

Keystone participated in numerous detailed cost-benefit analyses with the OEM companies, reviewing part after part for suitability for AM processes and looking for compelling cost reductions that would be the foundation for a strong business case. Given the high cost of powder metal and welding wire, the high capital cost of electron-beam or laser AM equipment, few good examples of cost reduction were identified that would inspire an OEM to substitute AM processes for castings or forgings.

In that timeframe, it was becoming obvious that the effort to qualify additive manufactured parts for use in flight-critical airframe and engine applications was becoming a significant roadblock. This constraint coupled with the difficulty to identify pervasive cost reductions by substituting additive manufacturing for existing manufactured components, proved that directed-energy AM processes would struggle to be a sustainable business.

Keystone’s strategy was to expand the range and market of parts that could be made using directed-energy additive manufacturing, focusing more on non-critical parts, tooling and the reconstructive repair of non-critical components. This greater market segment would, however, require a significant reduction in the per-pound cost of AM deposited metal. A cost breakdown of an AM process reveals that the primary drivers are the cost of raw material, the cost of capital equipment, and the machine and labor-based cost of time in the equipment. These factors drove to a simple set of conclusions that defined the path forward for additive manufacturing to establish a foothold in the broader manufacturing industry beyond just aerospace.

Low-Cost Raw Material

Welding wire is always a lower cost than powder metal and the cost for handling and management of the raw material stream is lower. There are far more alloys available as welding wire compared to powder metal. This raw material stream is highly mature, broadly distributed and is lower in cost.

Low-Cost Equipment for Large Parts

Electron–beam and laser AM processes require expensive equipment driven by the high cost of delivered and focused energy from an EB gun or laser. This represents a significant cost compared to an energy source such as an electrical arc delivery. A robotic platform capable of 6 or 7 degrees of freedom of motion in a very large work space is a very low cost alternative to a gantry-based CNC system supplying motion in an equivalent work space. A highly capable robotic welding platform can be acquired for $100 K to $200 K compared to millions of dollars for EB and laser systems. This led to the utilization of a robotic gas metal arc welding (GMAW) system as a robust, mature starting platform for a low-cost AM process using traditional weld wire as the principle material delivery system. Robotic welding systems are a very mature capability and represent a highly supported industry. The primary challenges with robotic AM processes are the lack of integrated process controls and the difficulty of programming for complex parts.

High-Rate Throughput & Deposition Rates

The up-time of robotic welding processes is very high, and the deposition rate for most alloys ranges from 7 lbs/hr to 25 lbs/hr. One operator can easily operate two to three robotic systems representing a low labor content.

However, one does not just take a robotic welder and become a qualified source for additive manufacturing processes. There are several other considerations required to make a capable AM system. Most significantly, closed-loop process controls need to be added to the robotic platform to build in a level of reproducibility and process consistency to provide confidence the material will be uniform. AM processes must be consistent, of predictable quality, be homogeneous throughout the AM build, consistently achieve minimum mechanical properties, and be equivalent from part-to-part, machine-to-machine and supplier-to-supplier. There are thousands of robotic welding systems throughout the country that could be placed into service performing AM processes, however without process controls, process specifications and procedures, qualification standards and certified mechanical property data bases, the output from these equipment platforms would be inconsistent, variable and lack reliability. The potential industry would falter and have strong negative perceptions.

The key elements needed for AM capability are process controls, written guidelines and specifications, and a solid path to qualification. Keystone is actively addressing these enhancements to make robotic pulsed-arc AM a qualified mainstream process.

The primary process controls that are needed to transform a typical industrial robotic welder to an AM capability are:

- Control of build height

- Control and management of part temperature during an AM build

- Monitoring the features of the melt pool during AM processing

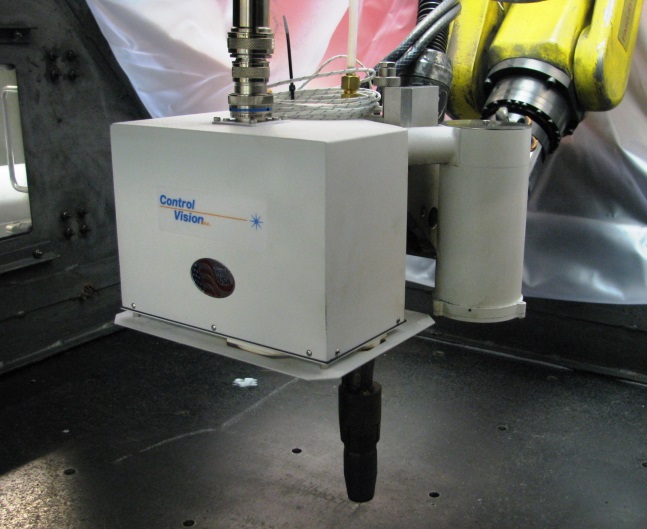

Keystone has developed an integrated suite of sensors and control software that can be added to a welding robotic system and communicate with the robot’s controller through analog and digital I/O ports. Figure 2 shows the Keystone lightweight integrated sensor head mounted on the robot end arm to provide closed-loop build height control, closed-loop thermal management and control, and melt pool size and feature measurement and monitoring.

Using these controls, Keystone has successfully produced a significant range of AM parts in many important alloys including titanium, aluminum, steel, iron-based alloys, nickel superalloys, cobalt alloys, and copper-nickel alloys. Parts and tools with over 550 lbs of deposited material have been produced at Keystone for production applications. Figure 3 shows several examples of AM parts produced by Keystone using robotic pulsed-arc methods. This capability, combined with a focus on very low cost and non-critical hardware, has enabled Keystone to expand the range of parts and tooling appropriate for AM processing, critical for the directed-energy AM market.

Keystone has generated AM source and process qualification guidelines for the robotic pulsed-arc process and facilities and is currently developing certified B-Basis allowable mechanical property data for titanium and stainless steel alloys in support of US Navy projects. Along with process controls, these guidelines and certified properties databases provide the foundation for qualification against the criteria for both non-critical and critical hardware.

Keystone continues to mature and expand the capabilities of add-on process controls for robotic AM platforms, working to have a package that can transform an industrial welding robot to a viable AM machine and process. Expanding large-part AM manufacturing into many industry sectors will be a critical aspect of building a robust manufacturing supply base and enabling directed-energy AM processes to get a foothold as a viable approach for producing large-scale metal parts.

Keystone has installed a second robotic AM system at its Port St. Lucie, FL facility to keep up with the expanding demand for low-cost large-scale additive manufacturing for aerospace and industrial applications. We invite you to visit Keystone at www.keystonehq.com and consider potential applications for this emerging addition to the traditional directed-energy AM processes.

Bryant Walker and Raymond Walker are President and Vice President of Keystone Synergistic Enterprises, Inc.