By Frank Geyer

Additive manufacturing, especially “3D printing”, is a hot topic for many industries. While 3D printing in plastics has already reached the consumer level, additive manufacturing processes using metals are more complex and require extensive material and process knowledge.

To understand 3D printing, it is important to first look at the three categories of manufacturing:

Subtractive manufacturing, or form alteration through material removal (i.e., machining), forming, or form alteration through heat or mechanical force (i.e., forging, bending), and generative or additive manufacturing which is the building of structures layer by layer (i.e., laser additive manufacturing, electron beam melting, laser metal deposition). In additive manufacturing, a three-dimensional object is created from a digital model. There are several metal based additive manufacturing methods available. This article will consider the two powder based laser additive processes: Laser Metal Deposition (LMD), also known as direct metal deposition, and Laser Metal Fusion (LMF), commonly known as powder-bed or 3D printing.

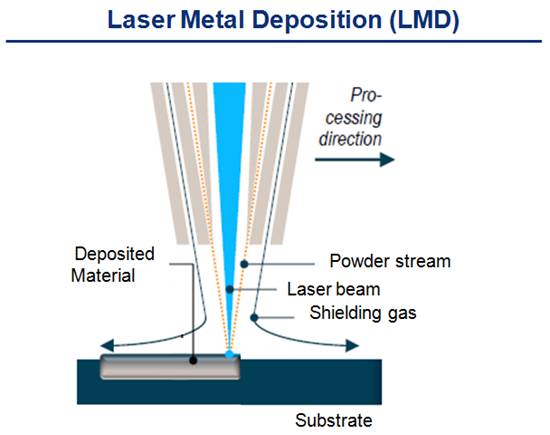

LMD utilizes a laser beam to generate a melt pool on the surface of the component (substrate). A stream of metal powder is blown into that melt pool and fused to the substrate. The result is a metallurgical bond between the coating and the substrate, providing a significantly improved bond compared to other coating or cladding methods.

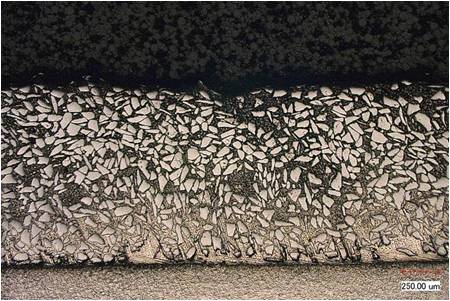

For corrosion protection, materials like austenitic steels and nickel based alloys are deposited while for wear protection martensite steels, nickel and cobalt based alloys and carbide particles embedded in metallic matrices (i.e., tungsten carbides in nickel base matrix) are used. Other materials can be deposited as well, depending on the application.

An advantage of laser cladding over conventional methods is the precision of the layers, both in overlap and size, combined with the minimal dilution of the added material with the substrate.

The dilution zone is so small that, for many applications, a single layer is sufficient enough to have undiluted material at the surface.

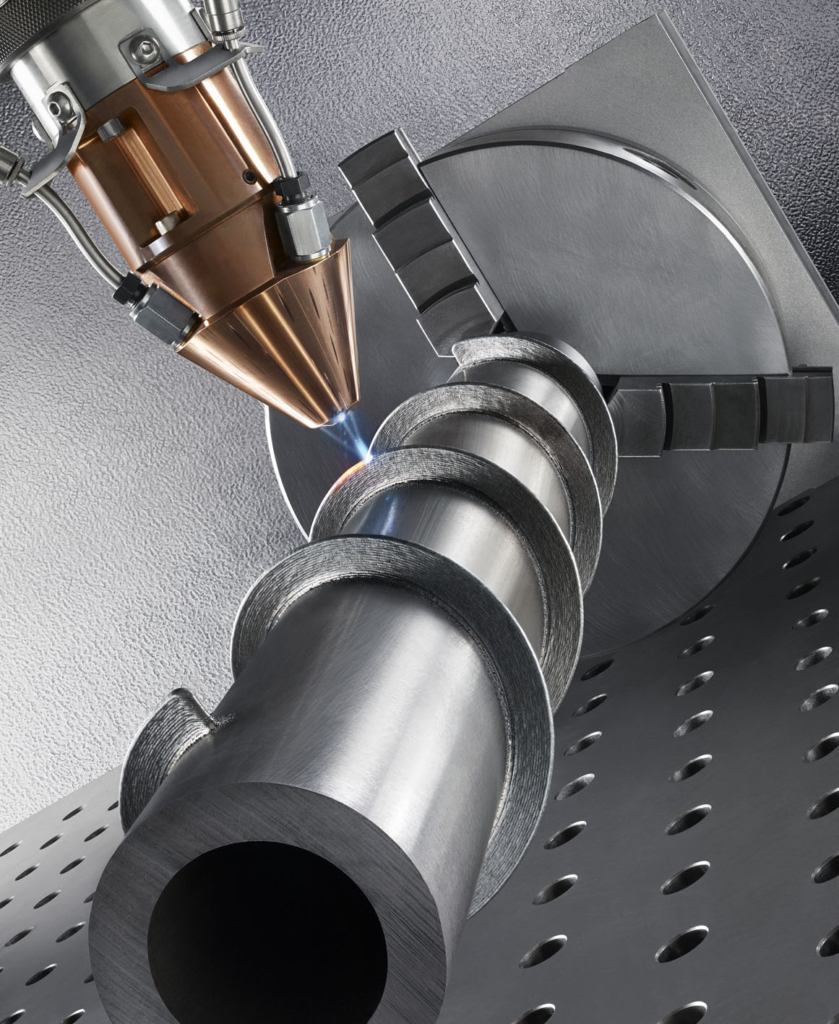

LMD can be used for a variety of applications. Cladding applications include valve seats or coating along the edge of cutting blades, both of which require a high wear resistance. Turbine blade and shaft repairs, as well as commercial diesel engine parts (pistons, heads) and die repairs, are also highly feasible applications. LMD can also be used for generating structures from scratch or by building up an existing structure, for example to reinforce parts for specific load cases. As a very versatile process, LMD can add significant value to manufacturing and MRO based companies.

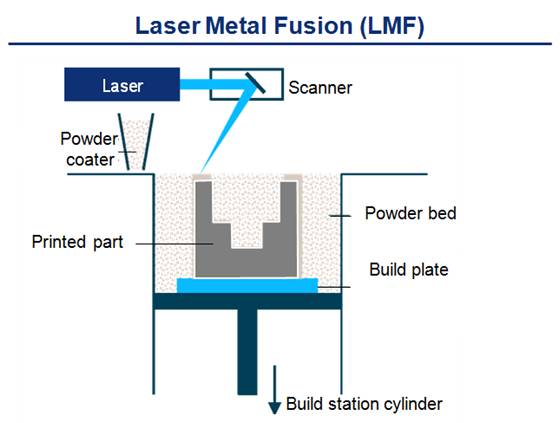

In contrast, Laser Metal Fusion (LMF) , or the process commonly known as metal 3D printing, is a powder-bed based laser fusion process that converts 3D digital data into a physical part, built up layer by layer. The part geometry 3D model is prepared in a special software that ‘slices’ the volume into very thin layers. Thicknesses between 20-100 µm are commonly used. A ‘scanning’ strategy is applied to each slice to optimize the fusion quality, part density and heat management throughout the build. Generating this file requires extensive material and process knowledge and is key to a successful build.

The LMF process starts with the application of a layer of metal powder to a substrate plate. The desired cross section of the geometry is then fused to the plate with a laser beam that is directed through a scanner optic. After the exposure the plate is lowered and the next layer of powder is applied. The process is repeated until the part is completed.

Build times depend on different factors, for example part size, layer thickness, materials, laser power, scanning speed and spot size and can range from several hours to weeks. While a print can be restarted if interrupted, the stopping point is always recognizable as the part temperature has changed. A dark line across the part shows when and where the interruption happened. Proper job preparation is crucial to avoid build errors mid-print, as you do not want to run out of powder half way through a three week job.

With the very high resolution of LMF it is possible to build fine and complicated 3D structures, to the extent that geometries that once required an assembly of several machined parts can now be redesigned and printed as a single part with the same or enhanced functionality.

Being able to produce internal and surface features within a single part also means that a completely different engineering approach is needed to fully utilize the advantages of this technology. Many restrictions and rules in designs that had to be manufactured by machining processes no longer apply. The 3D printed part design can have a complexity that is not possible to achieve otherwise. Engineers will have to learn how to design a part with such great freedom in complexity.

While 3D printing has become a buzzword that gets many people excited – and rightfully so –there is much more involved than just printing a part. When dealing with a metal in powder form, the grain size and structure are important and they play a significant role in the process as well as the final performance of the part. Currently there is a lack of powder manufacturing standards, specifically in regards to storing and handling, and a customer must be able to qualify powder prior to processing. In addition, the laser scanning strategy, laser power, spot size, choice of optics, cover gas and scanning path all affect the final structure. In the end, the resulting geometry is 100 percent welded, which in itself is a challenge for heat management and stress relief.

Once a build is completed the part needs to be removed from the machine. It then must undergo several post processing steps. The following actions do not necessarily have to be completed in this order, but all are required: post heat treatment (if higher densities are needed, this includes hipping), removal of support structures and the build plate, machining of any interface surfaces, and final surface treatments for example, bead blasting.

There are several industries already using 3D printing, including the dental , medical and prototype markets.

Hip joint implants, crowns and bridges made of materials such as titanium, stainless steels and cobalt chrome, are examples of these applications.

One of the interesting aspects of these industries is that although the quantity of parts produced is high, there is no serial production. In other words each part is unique.

In aerospace, the ability to generate hollow and light ‘bionic’ structures allows for structural designs that have not been possible with conventional manufacturing methods. The use of 3D printing in metal has already moved from initial tryouts and prototypes to serial production. It is not “coming.” It is already “here.”

Additive manufacturing with lasers enables users to repair and make parts that have advantages over conventionally produced parts, and it can even eliminate the need for assemblies. The precision of LMD, which allows design engineers to add material characteristics exactly where needed, and the high resolution, “complexity-for-free” 3D printing are manufacturing methods that can and will open new metal based manufacturing capabilities that can replace or complement currently used processes.

Frank Geyer is the product manager for Additive Manufacturing & Laser Systems at TRUMPF Inc.