By: Christian Freitag1,2, Margit Wiedenmann1, Jan-Philipp Negel1, André Loescher1, Volkher Onuseit1, Rudolf Weber1, Marwan Abdou Ahmed1, Thomas Graf1

In order to process Carbon fiber reinforced plastics (CFRP) with a satisfying productivity, average laser powers >1 kW are necessary. Usually high average laser powers are achieved using continuous wave (cw) laser systems but the appearance of thermal damage ranging from 50 µm to several mm was observed using cw lasers for CFRP processing. According to model predictions the absorbed intensity has to be larger than 108 W/cm² to achieve a thermal damage smaller than 10 µm. Today such high intensities are conveniently achieved with ultra-short pulse laser systems. However, the average laser power of such laser systems is usually too low for productive cutting processes. The IFSW thin-disk multipass amplifier allows for the first time ultra-short pulse laser processing of CFRP at an average laser power of 1.1 kW with pulse energies of 3.7 mJ.

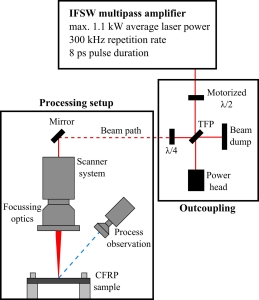

Experimental setup

A sketch of the experimental setup used in this study is shown in Fig. 1. The laser source is a thin-disk multipass amplifier for 8 ps pulses with a maximum used average output power of 1100 W. The laser has a constant pulse repetition rate of 300 kHz which gives a maximum pulse energy of about 3.7 mJ. The laser emits at a wavelength of 1030 nm with a beam quality factor M² < 1.4. A fast scanner system was used leading to a maximum feed rate of the laser beam of 30 m/s. The resulting focal diameter was calculated to be about 125 µm (1/e² intensity level). The CFRP samples used were Toray T700S-12k carbon fibers with a RTM 6 matrix which is a monocomponent resin. The samples were processed by ablating on a circular path with a diameter of 50 mm in a multi-pass process.

Heat accumulation effects as a limitation

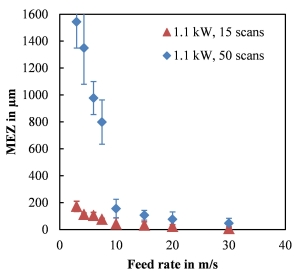

The heat affected area, where the matrix material is vaporized leaving blank carbon fibers, is called matrix evaporation zone (MEZ). The extent of the MEZ for different feed rates of the laser beam after 15 and 50 scans can be seen in Fig. 2. For both number of scans the extent of the MEZ becomes larger with decreasing feed rate. This is a consequence of the pulse-accumulation effect. Each laser pulse contributes to the heating of the processed material. This accumulation results in additional matrix damage if the temporal delay between consecutive pulses is too short for the material to cool down to almost its initial temperature. To limit the influence of the pulses-accumulation effect, the number of pulses applied at one spot should be reduced by choosing a high feed rate up to complete separation of the consecutive laser pulses.

Beside the pulse-accumulation effect, the scan-accumulation effect can also be observed in Fig. 2. For

an increasing number of scans, here from 15 to 50 scans, the MEZ increases significantly especially for low feed rates. The scan-accumulation effect is a major damaging mechanism when cutting CFRP with high average laser powers using a multipass process. Like the pulse-accumulation effect it also contributes to the increase of temperature in the compound but on a slower time scale. A characteristic parameter of the scan-accumulation effect is the number of scans above which the scan-accumulation effect causes additional matrix damage. The scan-accumulation damage develops, if a critical number of scans Ncritical is exceeded. Below this threshold, matrix damage is primarily caused by single-pulse damage or by the pulse-accumulation effect as can be seen in Fig. 2 for 15 scans. Above the critical number of scans, the matrix damage is mainly caused by the scan-accumulation effect as it is the case for 50 scans.

Cutting CFRP with high quality and high productivity

A rectangular shaped CFRP part was cut with 1.1 kW average laser power. To avoid the pulse-accumulation effect, a feed rate of 30 m/s was chosen. The influence of the scan-accumulation effect was reduced by a long cutting contour of 640 mm which increases the temporal delay between two consecutive scans. However, the scan-accumulation effect could not be completely avoided. Therefore, after each 200 scans, which are for this contour length still below the critical number of scans, a break of about 1 minute was implemented. The duration of this break was not yet optimized and is certainly much too long. The laser could be used for other processes during this break to further improve the productivity.

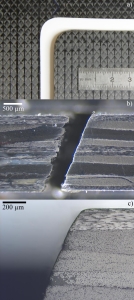

A view from the top on the cut work piece can be seen in Fig. 3a). It is noted that the gap between the inner and outer part does not represent the actual ablated kerf width. In total about 2100 scans where necessary to completely cut the material. With the applied feed rate of 30 m/s the effective average cutting speed was 0.9 m/min. By further optimization of the cutting process e.g. by ablating multiple parallel lines to increase the kerf width, an additional improvement of the effective cutting speed may be achieved.

The achieved quality of the cut can be seen in Fig. 3b) in a cross section. The inner part of the cut rectangle is shown on the right side while the outer part can be seen on the left. In Fig. 3b) some damage in the range of 200 µm is seen on the outer part. In Fig. 3b) and in the magnification of this part in Fig. 3c) it can be seen that the inner part of the cut has no measureable thermal damage.

Conclusion

A novel ultra-short pulse laser system with an average laser power of 1.1 kW, 8 ps and 300 kHz was used to process CFRP.

Ablation experiments in CFRP with different feed-rates revealed the impact of the pulse-accumulation effect on the formation of the matrix evaporation zone (MEZ). For lower feed rates and therefore higher pulse overlaps the MEZ increases. A very important influencing factor on the MEZ formation is the scan-accumulation effect. This effect can lead to a burning of the matrix material and therefore to vast thermal damage. A characteristic value for the scan-accumulation effect is the critical number of scans above which the extent of the MEZ starts to increase very rapidly.

To demonstrate the capabilities of the used innovative laser source, CFRP has been cut with an effective average cutting speed of 0.9 m/min and no measureable thermal damage on the inner part of the cut rectangle.

1 Institut für Strahlwerkzeuge IFSW, Universität Stuttgart, Pfaffenwaldring 43, 70569 Stuttgart, Germany

2Graduate School of advanced Manufacturing Engineering GSaME, Universität Stuttgart, Nobelstraße 12, 70569 Stuttgart, Germany